- cross-posted to:

- technology@hexbear.net

- technology@lemmy.ml

- cross-posted to:

- technology@hexbear.net

- technology@lemmy.ml

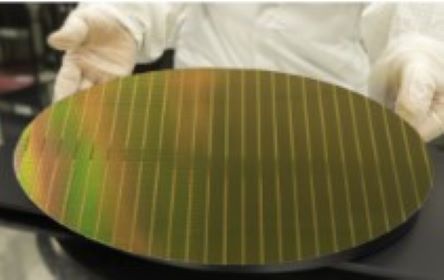

the T150 A demonstrates an extreme resolution of 120nm during the lithography process

This sounds like a very large feature size given the existence of 3-5 nm process nodes. Or am I missing something here?

The process node is not a real resolution, just a marketing term, feature sizes for 5 nm are in the few tens of nanometers. And chinese foundry SMIC uses quadruple patterning to get those feature sizes from less powerful lithography tools.

The photoresist is a component of photolithography, but doesn’t determine the process node on its own. The 120nm quoted here is quite advanced compared to the capitalist products I have found advertised (200nm or so).

Photolithography (also known as optical lithography) is a process used in the manufacturing of integrated circuits. It involves using light to transfer a pattern onto a substrate, typically a silicon wafer.

The process begins with a photosensitive material, called a photoresist, being applied to the substrate. A photomask that contains the desired pattern is then placed over the photoresist. Light is shone through the photomask, exposing the photoresist in certain areas. The exposed areas undergo a chemical change, making them either soluble or insoluble in a developer solution. After development, the pattern is transferred onto the substrate through etching, chemical vapor deposition, or ion implantation processes.