phillips worst screw self stripping garbage

That is actually a feature of this design. They were the answer to in-line screwdrivers who had no precise stopping torque: cam-out before the thread is damaged.

I know it’s an intentional feature, but it’s a bad feature. Camming out damages the head of the screw. This exchanges repairability for manufacturing simplicity. Additionally, the sloped shape makes it possible to use slightly oversized or undersized drivers, further increasing the chance of camming out and damaging the screwhead.

Anyone who willfully uses a slotted screw on a new project in the presence of even somewhat reasonable alternatives should have a lifetime ban on designing any items for anyone.

Also, use Robertsons, gink.

it’s single valid use: somewhere that you may not have tools but might require an impromptu fix… preferably paired with a much larger screw than technically required so you can use things like coins as a driver

Yeah, like mounting plates for cameras…. Um, I think that’s the only place I’ve appreciated a slot screw

Sewing machine too! Always using scissors to open that slot screw to change the needle

We put slots on the thumbscrews used on some of our connectors for military radios. This was a soldier can open or tighten them down with a knife blade.

The torx are the most resistant, the rest can also cease to exist.

Torx is great but fuck security torx

security torx

Do you know what’s the deal with them except having to pay / find extra bits?

If you’re determined enough you can jam a slot screwdriver in a torx and turn it, the security bit makes it so that you have to be REALLY determined when you jam the slot screwdriver in

They’re designed so the average person isn’t gonna have the tools to mess with them.

Most of the sets I own have a hole in them, so I think for the scenario that the average person does actually have a torx set, the chance is pretty high that it’s also one that they can use on those “security” torx screws. So I don’t see them that much more secure than regular torx. The only reason I could think of is that you also can use a normal screwdriver to unscrew a torx, which is harder to do with that extra pin. But it can still be done^^

Removed by mod

I strongly dislike how many times I’ve stripped a Phillips and used a die grinder to force it to become a flat. Torx is fine.

I used to restore “barn bikes”, most of them were Japanese. It took me a while to figure out the difference between Japanese Industrial Standard (JIS) and Phillips screws. Of course over the years, a lot of the fasteners had already been cammed out by previous owners using a Phillips screwdriver in a JIS screw. I had to resort to the die grinder method far more than I’d have preferred.

My favorite is hex, self centering and doesn’t strip easily

Hexagons are the bestagons

Only in 2D. Screws are 3D. There is no known optimum in 3D.

Removed by mod

Torx tools are cheaper? I didn’t know that. I’ve never really come across them, so I didn’t think they were an option for universal replacement.

Removed by mod

Unless they are in a facemill or something for a milling machine

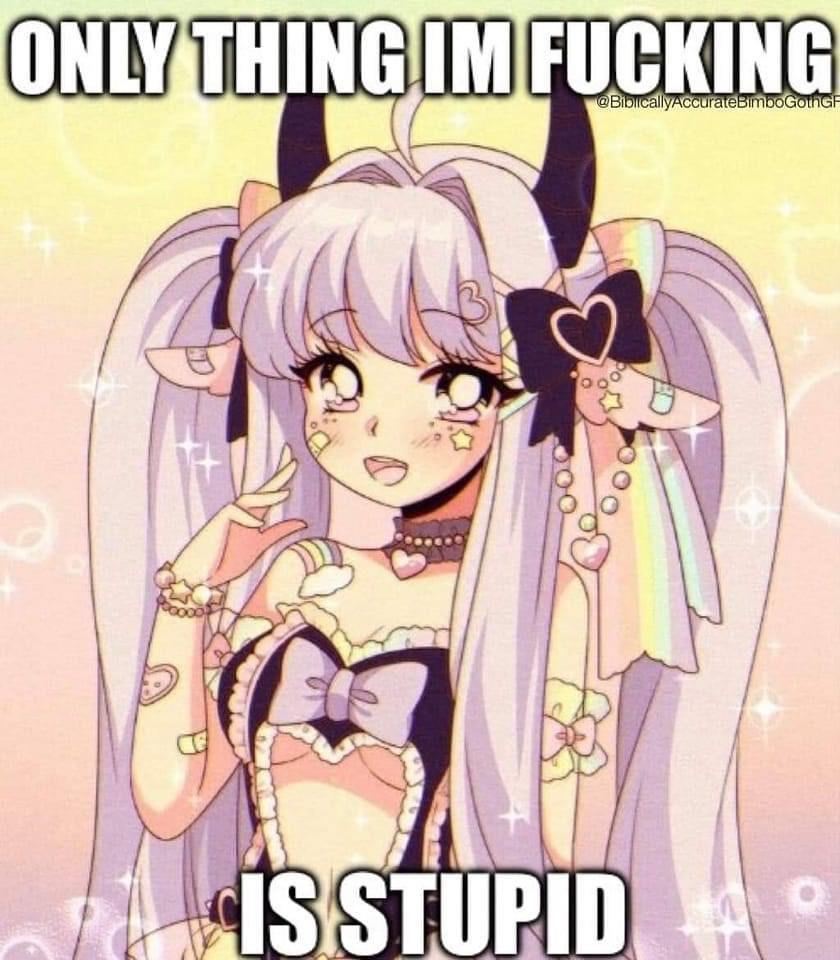

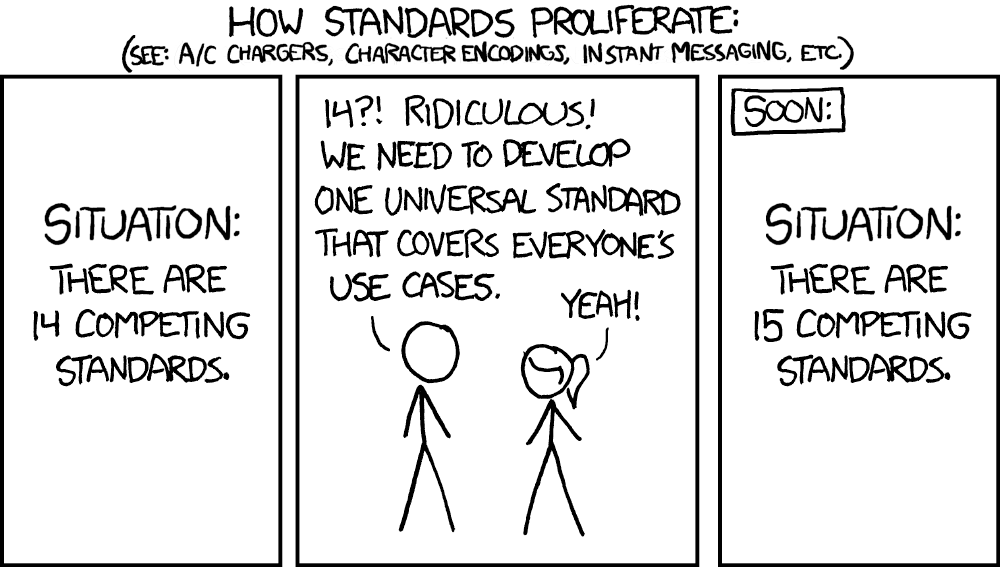

Situation: There are 20 screw standards.

John Corporate: “20 standards… I know, I’ll create a new type of screw that will be unique to my corporate overlords and prevent users from repairing their own devices!”

Situation: There are 21 screw standards.

Relevant xkcd:

To be fair, UTF-8 did win the character encoding wars. Kudos to the Unicode designers I guess.

USB also won the cable data war. The 2000s era cables is wild

Yeah, given enough time sometimes one of the standards will win and kill the others, it kinda just depends (in part on luck)

Wish Windows knew that

Hex screws are sick tho. Great when there isnt much space to tighten regular screws.

Square is called a Robertson and is the standard for construction in Canada. None of that bullshit Phillips trash.

Canada is a very progressive place it seems

Not only the standard screw but a very effective head shape. The head is both self centring and can hold on the screw securely and without the use of magnets.

I will die defending Robertson screw as a top contender. The rest of the world must learn our superior Canadian ways, by force if necessary.

It’s 100% superior to anything else I’ve used. If you use a good quality screw driver or bit, they’ll NEVER strip, even using an impact driver.

The real “actual screw”.

I like pluses and squares. Minuses need to be removed from existence

Minus is great because you can use a butter knife on a pinch to unscrew/screw it

Torx or Robertson, are the only ones worth a damn.

I’m a Philips type of guy myself.

6-lobe is life. I got a box of them for a set of stairs I had to rebuild, and the sheer ease of use makes me never want to go back.

Never heard anyone call Torx “6 lobe”. But yes, Torx all the way.

That’s what it’s called on the image and tbh I’ve never been quite sure what a “torx” was until now.

Torx is the only head that needs to exist. The rest can go fuck a rusty chainsaw.

Square is really good too.

Phillips and flat head bits fit in a variety of sizes of screw heads. We seem to have chosen convenience over performance.

This guy screws

And then bolts

We stan Phillips/slot

Phillips/slot: the pansexual of screwheads

Hex is the best, cmv